I had been in crystal trophy design and production for a long time and it often occur to me that my clients do not understand what is best print on crystal trophy and I need to explain in details. Hence, I took the opportunity to share my knowledge to interested buyers by making a short blog regarding different print effects. The word “print” is incorrectly used, as there are laser engraving and sandblasting, but I will stick to the word “print” for ease of communication.

There are 5 types of printing of logo and text; sandblast, sandblast with infill colour, internal laser engrave, full print as well as UV print. Let me explain in details. Each has its own advantages and disadvantages and I will show you what I had learnt.

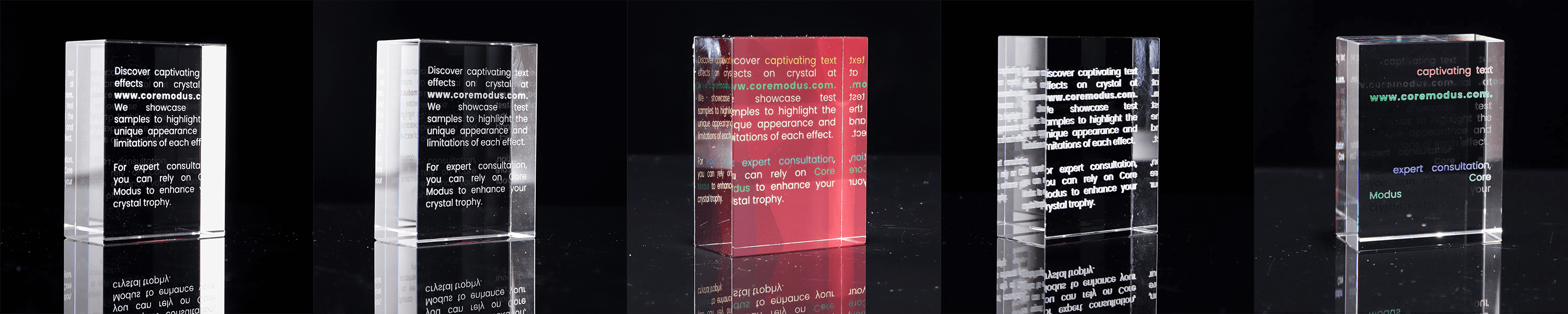

Sandblasting

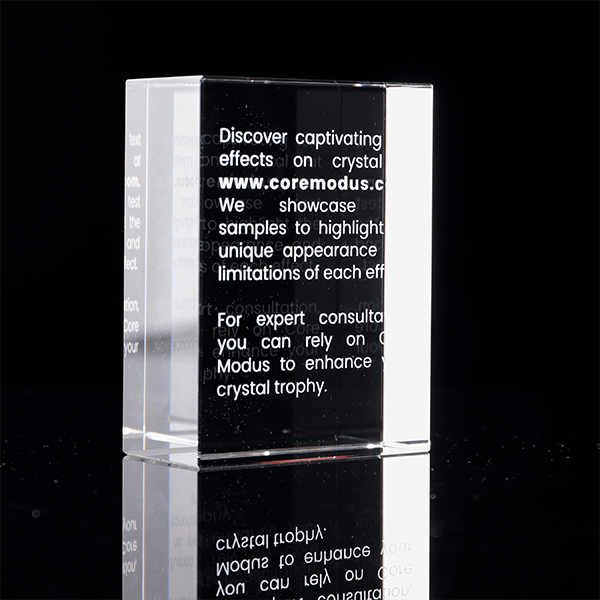

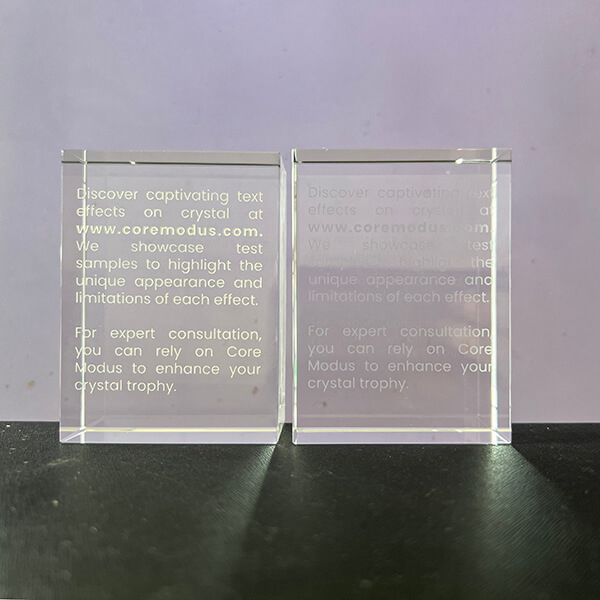

Sandblasting is the oldest technique to print logo and text. It is done blasting tiny particles to the exposed surface to create the effect. For the effect, the best explanation is that the print is matte (rough) on the smooth surface. This technique is proven to be best if done of curved surface and other coloured crystal. Usually, this print can be seen on most lighting, but if you are using clear crystal against white background, the print is not easy to be seen.

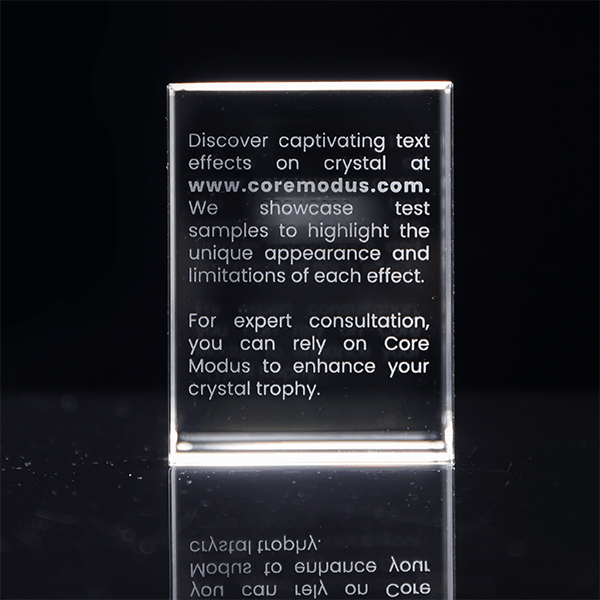

Sandblast with infill (left) vs Sandblast (right) on a white background

Sandblasting with Colour Infill

This is a variation of sandblasting but we add colour to the sandblasted (matte) surface for clear and coloured crystals. The standard infill colours are black, white, red, blue, green, etc. Usually, the common colours to use are white and black. If white infill on clear crystal, the visibility is slightly higher than just sandblasting as shown as attached. This is good if you willing to spend a bit more to increase visibility. There is disadvantage though, the infill is most suitable for text with thin lines but not good to apply if the matte area is wide such as big thick text or logo.

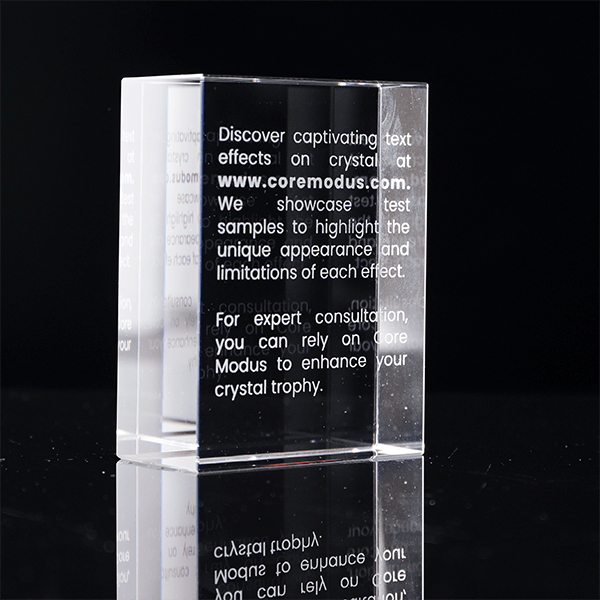

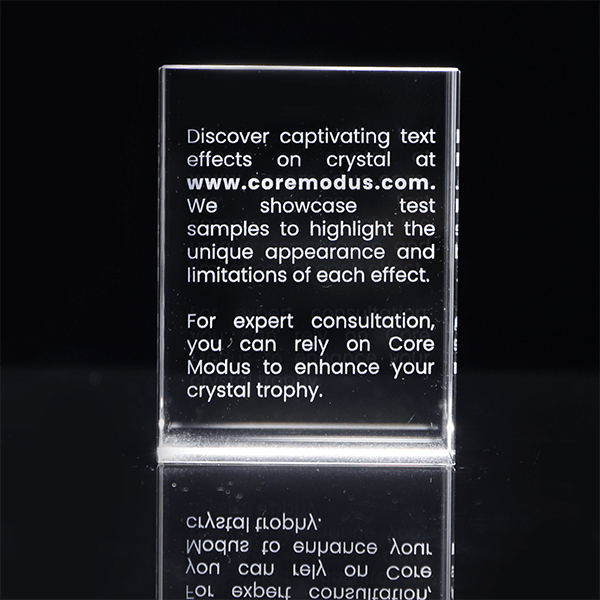

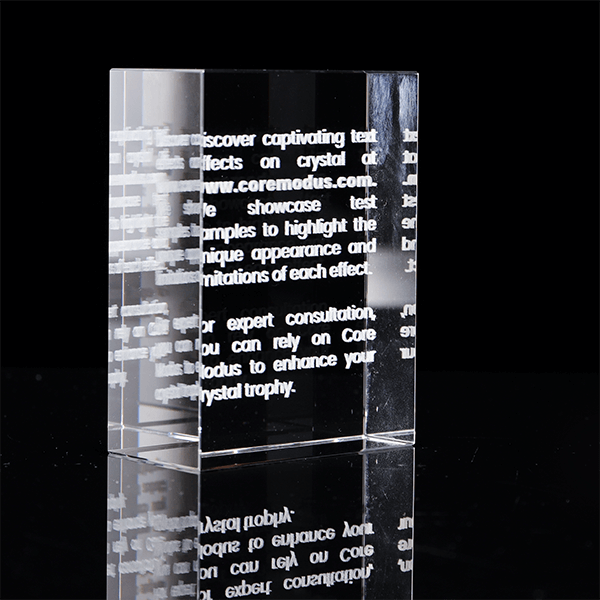

2D Internal Laser Engraving

This is another popular method to print text and logo in crystal trophy. This print is done subsurface and can only be done if surface is flat. The advantages of this 2D internal laser engrave are cheap, can do greytone and match with any 3D laser objects. In term of visibility, I can say it is same as sandblasting. Usually, client would ask if we can do colour laser engraving but unfortunately, we not able to do this colour technique as of now.

Full Colour Print

This print method is done by printing full colour film and sandwiched between the crystal and a thin glass. This technique is applied to the back part of crystal , can have 0%/ 50%/ 100% opacity and can have full colour print. Usually, full colour print are more suitable for background printing but there are clients who opt to include text and logo too. The print is scratch resistance but it is limited to be used on wide areas of about 20x20cm.

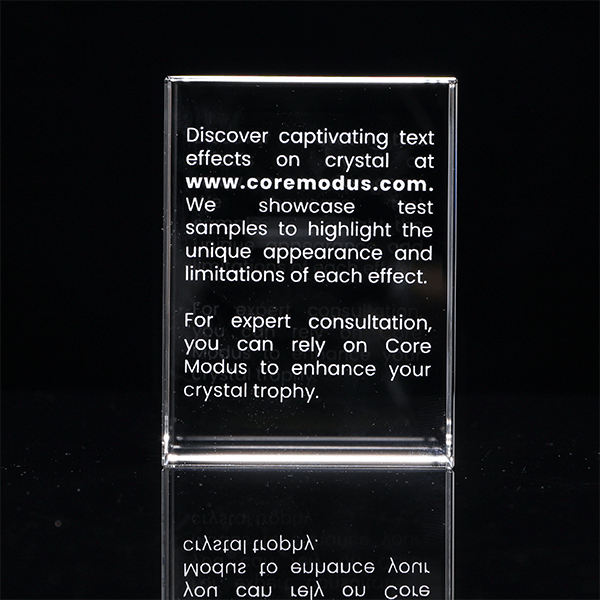

UV Print

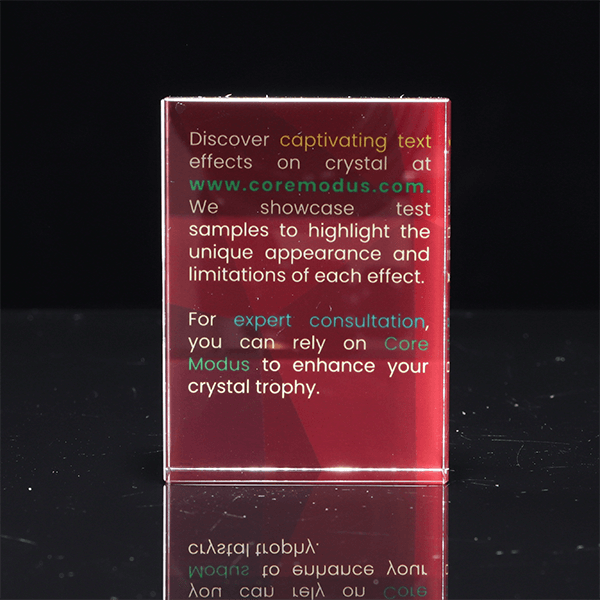

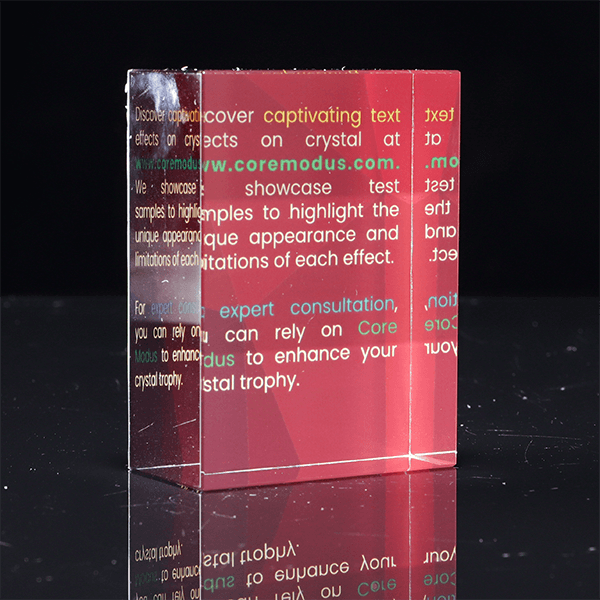

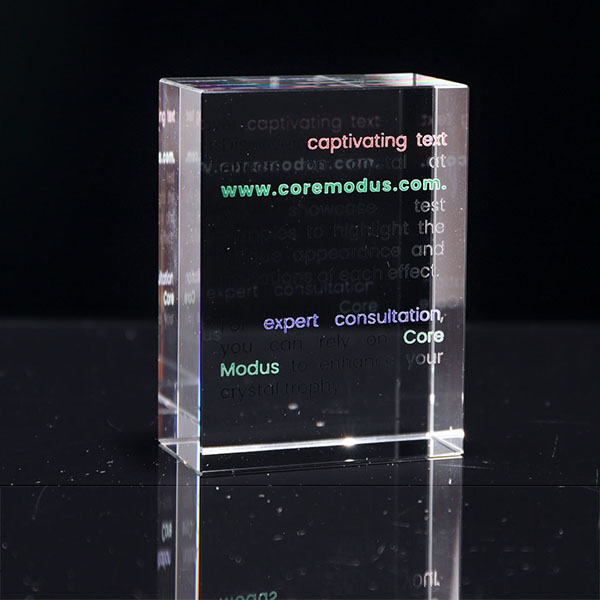

This print method is one of the latest technique and still evolving. You can print full colour text and logo onto the flat surface of clear and coloured crystal. The print colour is vibrant and you can feel the texture of print on the crystal. The text is not very scratch resistance but as trophy is not handled roughly, the print is just fine as display. Current UV print technique are mostly on flat surfaces but there are potential to print on curved surface using new UV printer.

There are many other custom products we made over the years. You can visit our product page to see the list. If you would like to custom made a new product for gift, you can contact us for discussion. Before that, you need to have an idea of your budget and general design and ample time for design and produce.